Veterinary Dental X-rays: A Quick Guide to Safety and Compliance

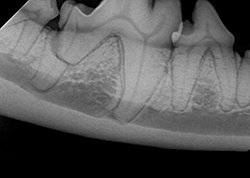

Veterinary Dentistry is a rapidly growing field in Veterinary medicine. An important piece of veterinary dentistry is the use of X-ray’s to view areas in the mouth that are unable to be seen by the naked eye. What most people do not know is that a large percent of animals develop dental diseases early in life that can be prevented from a dental checkup. With the increase in dental disease comes the increase of dental X-rays and it is important to not only know the benefits of x-rays but also how to stay safe and compliant.

X-rays are a type of ionizing radiation, which is radiation that carries enough energy to free electrons from atoms or molecules, thereby ionizing them. Ionizing radiation is made up of energetic subatomic particles, ions or atoms moving at high speeds (usually greater than 1% of the speed of light), and electromagnetic waves on the high-energy end of the electromagnetic spectrum. A dental x-ray radiograph is no different from that of an extremity or the torso and should be treated the same. A single dental radiograph is equal to the exposure a person receives from background radiation in a 24 hour period. Although this is low, multiple exposures throughout the day, week, and year start to build up. There are several steps you can take to protect the patient, yourself, and other employees from radiation exposure..

ALARA

ALARA stands for As Low As Reasonably Achievable. ALARA is not only a great way to limit exposure, it is required by law and is mandated by the United States Nuclear Regulatory Commission Title 10 Section 20.1003. ALARA applies to stationary, mobile, and handheld x-ray units, there are no exceptions to the rule.

The Practice of ALARA is simply to keep your dose level as low as you can, this can be accomplished by a few simple ways:

Distance: The greater the Distance between the worker and X-ray housing, the lower the exposure. Try and keep distance from the primary beam and tube housing at all times, this avoids exposure due to scatter and leakage from the source. Also, avoid animal holding during exposures unless it is absolutely necessary. Doubling the distance between your body and the radiation source will divide the exposure dose by a factor of 4.

Shielding: Lead and concrete will attenuate x-rays and provide adequate protection during exposures. Examples of shielding are lead aprons, gloves, glasses, and thyroid collars. Other shielding options you may install are lead lined doors and shielded control rooms, check with your state to verify what kind of shielding you are required to have. The hand held timer on dental x-ray units allow the operator to be at a far enough distance during exposure that additional shielding may not be necessary.![]() Time: Reducing the time of exposure can directly reduce radiation dose. Dose rate is the total amount of radiation absorbed relative to its biological effect. Dose rate is the rate which radiation is absorbed. Therefore, the less time spent exposed to radiation, the less dose you receive.

Time: Reducing the time of exposure can directly reduce radiation dose. Dose rate is the total amount of radiation absorbed relative to its biological effect. Dose rate is the rate which radiation is absorbed. Therefore, the less time spent exposed to radiation, the less dose you receive.

Dosimetry: Measures your exposure during a specific time period. Some states require you to wear rings or badges, but it’s always a good idea to wear dosimetry. Dosimeters do not protect you from radiation, they only measure your dose.

Digital Sensors: Another way to limit exposure is to use digital sensors instead of the old fashion x-ray film. Digital sensors can help reduce exposure by using up to 50% less radiation to capture an image. Other advantages include bypassing chemical processing and the ability to digitally transfer and enhance images as well as eliminate costly x-ray film.

It’s very important to understand how to protect your medical staff and patients when working around high frequency radiation and to be aware of ways to reduce the level of radiation exposure. It takes a team effort to successfully implement the ALARA principles. ALARA should be a routine element of your work in radiological area.

Personal Protection

Lead (Pb) lined material is the most appropriate protection method against radiation. Lead is a metal which has the property of blocking/ absorbing x-ray radiation due to its high density. Hence lead sheets or shielding are used in the world of radiology for protection from x-ray. Various thicknesses of pure lead provide different levels of protection.

The following list gives a comparison of protection provided by various lead thicknesses when x-ray machine is set at 80kV (typical X-ray setting).

0.01 mm Pb - 25% protection from x-ray radiation

0.04 mm Pb - 55% protection

0.10 mm Pb - 70% protection

0.125 mm Pb – 80% protection

0.25 mm Pb - 96% protection

0.35 mm Pb - 97% protection

0.50 mm Pb - 99% protection

1.00 mm Pb - More than 99% protection

On top of good practices you should also have good personal protection. The minimum for most states will require you to provide at least 0.25 mm lead equivalent radiation absorbing material.

Maintaining Compliance

Each state governs their own radiation control program, which can be tricky. Before purchasing an x-ray it is a good idea to review your states regulations and requirements. Pre-operational evaluation of shielding and operating procedures may be required before routine use of such machines can be authorized. The importance of planning cannot be over emphasized as adequate lead times must be allowed to review facilities that require new construction or remodeling.

n Shielding Plans: Shielding plan reviews are an analysis of a proposed location of an X-ray unit for safety and compliance with the applicable state rules. The design of a proposed X-ray location must include engineered controls that will maximize radiation safety

to the public, patients and the unit operators. A well-planned design will reduce the safety burden on the x-ray operator and allow more focus on patient care. Contact us to find out more about having a shielding plan completed for your site.

n Radiation Surveys: Some states require a Qualified Expert perform an area radiation survey once the machine has been installed to determine dose rate at different points in the room and outside the room. This will most likely take place after a shielding plan has been submitted.

n Facility and Machine registration: Most states require that your facility is registered with the state as a radiology or radiation producing facility in order for them to track how many x-rays facilities are in the state. Also, you must register each radiation producing machine within 15-30 days, state depending, upon installation. To register, you will must go to your states Radiation Control or Department of health website or you may receive a copy or guidance on how to obtain registration from Covetrus.

n Training: All affected employees who handle radiation producing equipment must receive proper training on doing so. This training must be adequate from your states prospective and must be well documented. Training topics to be covered include: ALARA practices, use of the machine including positioning and handling for exposures, personal protective equipment, warning signs such as lights and alarms, required postings, and what to do in case of emergency.

n Quality: Your state will also require a Quality Assurance program, which covers everything from operating procedures to training logs to quality checks. Each state may differ on what they require from a quality standpoint so it is always a good idea to check with their offices. A radiation safety manual detailing potential hazards, responsibilities, an overview of important requirements mandated by the state, and occupational dose limits and exposures also must be present in a facility that contains Dental X-rays.

Covetrus is committed to making sure you have the tools necessary to meet your State’s Radiation Agency requirements. At the time of your purchase, we will review your State’s Radiation Regulations and provide you with a guidance letter that includes contact information and web-site information, a Radiation safety manual tailored to your states requirements, and a basic quality assurance program to help you get started. Contact Kevin Patterson in the Regulatory Affairs Department for more information about veterinary x-ray equipment, compliance, and safety.

About the Author

Kevin Patterson is a graduate of The Ohio State University with degrees in Microbiology and Chemistry. He has a strong background in compliance and safety working for The Ohio State University Wexner Medical Center in clinical Microbiology and Chemistry as well as the safety officer for the Critical care lab. He has also worked for Ohio State as a health physicist, working with the colleges of Pharmacy and Biological Sciences as the Radiation and X-ray safety officer. As the Regulatory Affairs & Quality Analyst with Covetrus, Patterson is accountable for radiation and x-ray compliance and OSHA safety consulting.

Need Regulatory Assistance

If you need help with regulatory or licensing issues, we're happy to help. We have a wide variety of resources to help you when issues arise.

Careers

Are you looking for a place to let your talents shine? At Covetrus, we help our practitioner customers better serve their patients and take pride in providing the best customer experience possible. Search our open positions to see our available opportunities.

Newsletter

Stay current with what’s going on with Covetrus, subscribe to receive our newsletter and email communications. Subscribers will receive the latest information in practice management, sales and marketing, animal health, and more.

Leave a comment